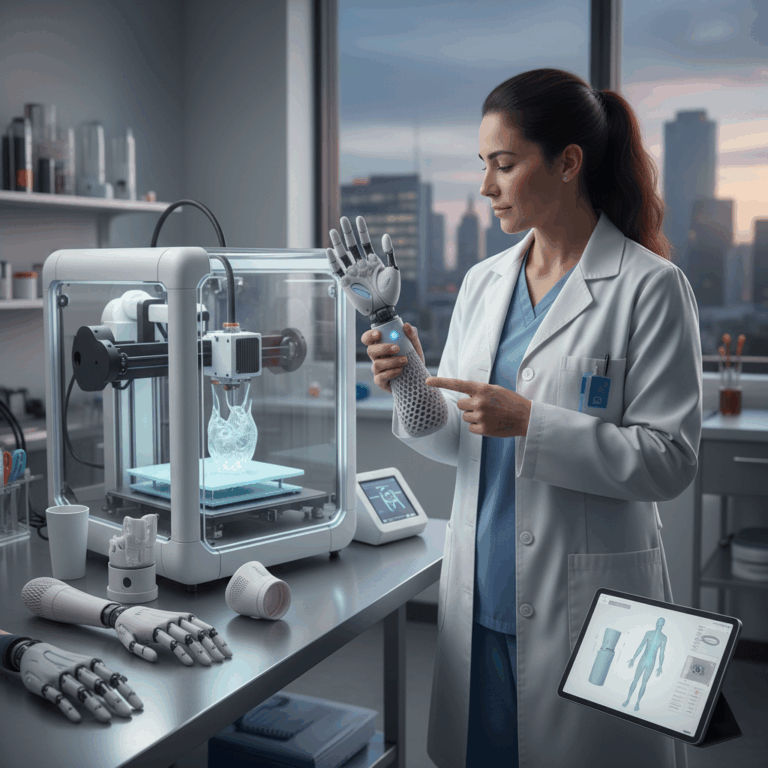

3D printing has emerged as one of the most disruptive technologies in modern medicine. Its most notable impact lies in the creation of personalized medical prosthetics, where precision, speed, and affordability have completely transformed the way medical devices are designed and manufactured. What once required weeks of waiting, high costs, and manual adjustments can now be achieved in days using cutting-edge additive manufacturing technology.

Personalization as a Key Factor

One of the greatest advantages of 3D printing applied to medical prosthetics is the ability to customize each device. Unlike traditional methods that produce standard pieces requiring manual adaptation, 3D printing utilizes precise anatomical scans of the patient. This ensures a natural fit, reduces discomfort, and improves mobility.

3D Scanning for Accurate Measurements

Body scanners capture millimeter-level details of the residual limb or affected area. The benefits include:

- Designing prosthetics according to the patient’s actual morphology.

- Avoiding manual errors that could cause chafing or discomfort.

- Accelerating the digital design process in minutes.

The result is a prosthetic that is more comfortable, functional, and stable, optimizing patient experience and rehabilitation outcomes.

Cutting-Edge Biocompatible Materials

Advancements in biomaterials have enabled 3D printing to produce prosthetics that are durable, safe, and versatile. Commonly used materials include:

- Flexible TPU for mobility and comfort.

- Modified PLA, combining strength and lightweight properties.

- Biocompatible nylon for long-lasting prosthetics.

- Certified medical resins for specific applications.

Material selection is based on the type of prosthetic, patient activity level, and clinical requirements, ensuring an ideal balance of functionality and comfort.

Advanced Medical Applications

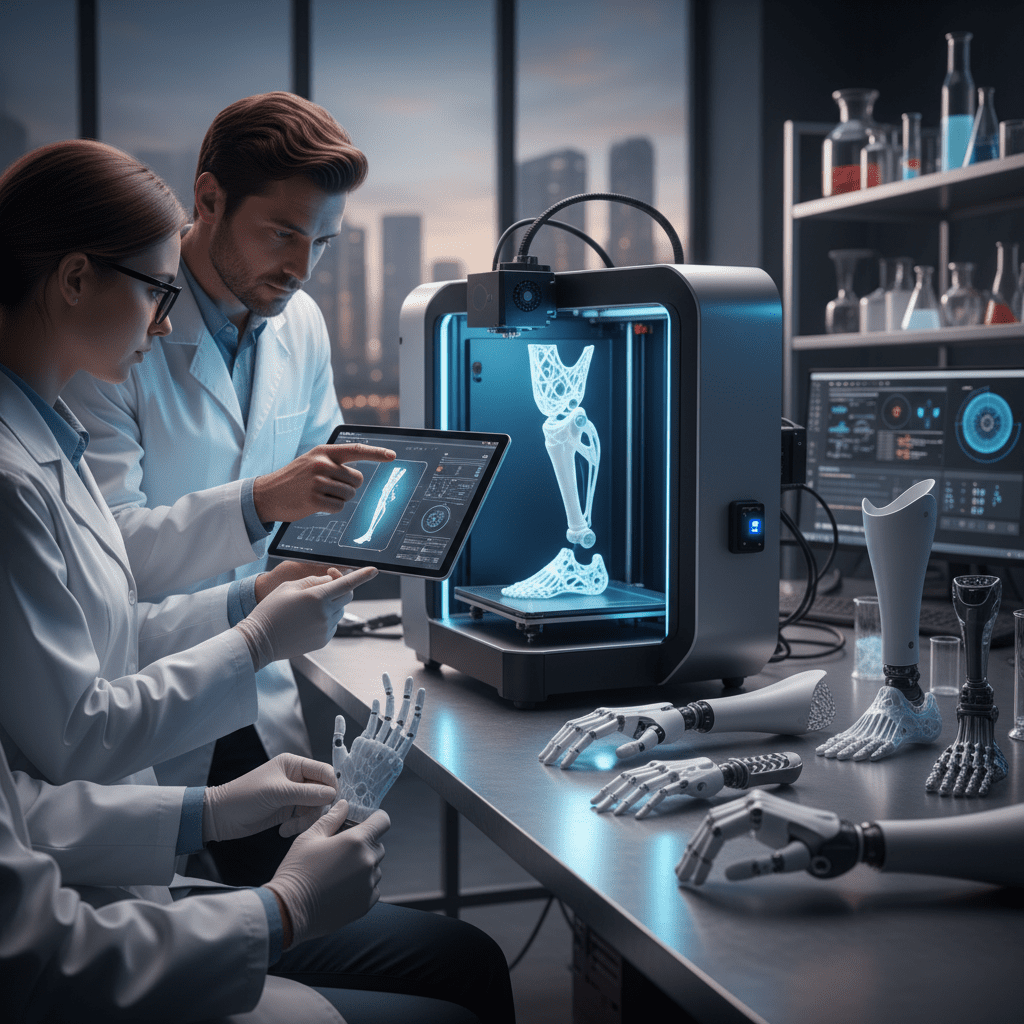

Beyond traditional prosthetics, 3D printing has unlocked new possibilities in medicine.

Anatomical Models for Surgery

Surgeons can now print exact models of organs, bones, or tissues before complex interventions. This enables:

- Practicing surgery on a realistic model.

- Reducing surgical risks and errors.

- Optimizing operation times.

These models have been crucial for performing complex surgeries with increased safety and better clinical outcomes.

Custom Implants

Cranial, maxillofacial, and orthopedic implants are produced using 3D printing. Their advantages include:

- Exact anatomical fit for the patient.

- Use of biocompatible and metallic materials.

- Reduced risk of rejection and complications.

Bioprinting: The Near Future

Bioprinting uses living cells to create tissues and, eventually, fully functional organs. So far, it has enabled the production of:

- Human skin for grafts or advanced healing.

- Functional cartilage for orthopedic interventions.

- Vascular structures for regenerative research.

In the near future, fully personalized organs could be printed, ushering in advanced regenerative medicine and custom transplants.

Benefits for Patients and Healthcare Systems

The adoption of 3D printing in medicine offers multiple benefits for both patients and healthcare providers:

- Cost Reduction: Prosthetics that once cost thousands of dollars are now accessible.

- Shorter Wait Times: From weeks or months to just days or hours.

- Better Adaptability: Prosthetics designed specifically for each patient provide comfort, mobility, and improved quality of life.

- Easy Replacement or Repair: Digital models allow for quick reprinting of worn or damaged parts.

Success Stories in Modern Medicine

3D-Printed Prosthetics for Children

Children require frequent changes due to growth. 3D printing allows:

- Reduced and affordable costs.

- Customization with colors and appealing designs.

- Easy replacement as the child grows.

Functional Prosthetics in Remote Areas

Organizations use 3D printers to manufacture prosthetics in remote regions, granting mobility and independence to people who previously lacked access to quality devices.

Realistic Aesthetic Prosthetics

Advances in technology allow for prosthetics with:

- Realistic skin texture.

- Natural coloring and precise anatomical patterns.

- Aesthetics that enhance social integration for patients.

Promising Future for Prosthetics and Personalized Medicine

The future of personalized medicine combines 3D printing, artificial intelligence, and smart biomaterials. Prosthetics will be able to:

- Connect with the nervous system.

- Detect pressure, heat, and movement.

- Automatically adjust to the user.

Bioprinting continues to advance toward fully functional, custom-made organs, while 3D printing technology redefines the limits of modern medicine and improves patient quality of life.